International Patented

- Over 800 Days R&D

- 20000+ times Analysis & Experiments

- 5th Generation Innovation

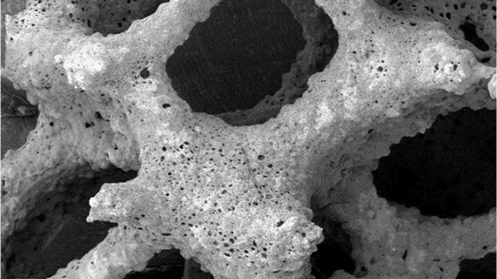

1200 Degrees

ultra-high temperature firing

100 Million

microspores evenly distributed

2.4 Times

E-liquid supply area

35%

increase in E-liquid transfer speed

Food Grade Formulation and Process

Pure food grade material, the ceramic elements and atomized aerosols have passed strict safety certification

Built for Sensation

Unparalleled Vaporization Efficiency

Designed for True Flavor

-

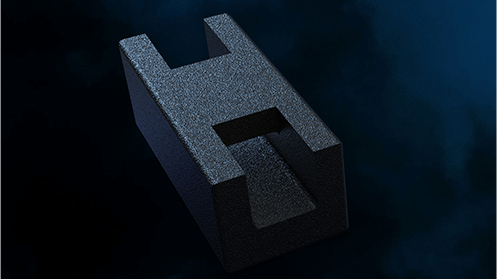

The physical structure has been optimized for our patent shape design and size, 2.4 times increase of E-liquid supply area. which improves the atomization efficiency of the heating element and saves more than 20% of energy.

-

By constantly optimize the ceramic pore scheme and heating track design, Purlava™ ensures perfect transmission and atomization of the e-liquid, at the same time to avoid e-liquid leakage, to achieve a perfect taste experience.

Bigger Vapor Creation

Purlava™ inside , the device can achieve stable vapor from the first puff to last, the TPM is 7 which is totally higher than the market level.

Automatic Production

New manufacturing process for ceramic and its metallization is developed for high production efficiency and quality consistency, which is a great improvement for sustainability